Key Topics

Fix the engine oil leak problem in your car

Most common problem with engine oil is leaking. Check the article to know the causes and how to fix the engine oil leaking problem

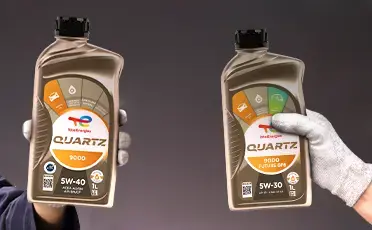

Which engine oil viscosity is best for your car?

There are many factors that should be taken into consideration when you want to choose the engine oil for your vehicle.

Original VS Fake Oil

Read on to know the most important things you should look for when trying to find the best oil.

News & Events

-

14/10 2025